Heat Management Textile

Automatic Nesting Solution

Heat Management Textile

-

BBQ gasket made of fiberglass terminated door seals Grill sealing high temperature thermal seal with clips

Thermo gasket is a resilient textile gasket designed for high temperature applications. The

outer surface is composed of multiple intertwined fiberglass yarns that form a rounded

tube. The inner core is fiberglass knitted rope. It is used as thermal seal in environments

with high temperature. In addition, the clips allow for quick , easy and cost effective

production assembly. The end is joint 3M type 69 white glass adhesive backed tape. -

Fiberglass knitted tape glass seal high temperature resistant seal for oven stove door self adhesive fiberglass gasket

Knitted fiberglass tape is a thin textile gasket designed for high temperature applications. The fiberglass tape is used with oven door stove door or grilling closure. It is produced with air texturized fiberglass filaments. It is specially designed for installations where glass panels are installed with steel frames. In normal working conditions as the steel frame expands due to dilatation in high temperature areas, this type of tape acts as a flexible separation layer between steel frames and glass panels.

-

Single Bulb tadpole gasket for ovens stoves fiberglass braided seal anti high temperature applicance

It is a highly resilent textile gasket designed for high temperature applications. The outer surface is composed of multiple intertwined fiber glass yarns that form a rounded tube. To improve the resiliency of the gasket, a special supporting tube made of stainless steel wire is inserted inside the inner cores. This allows a superior life cycle while keeping constant spring effects.

-

Thermo gasket steel wire reinforced round gasket fireplace gasket heat resistant seal

RG-WR-GB-SA is a resilient texitile gasket designed for high temperature applications. It’s composed of multiple intertwined fiberglass yarns that form a rounded tube.

To further facilitate the installation onto the frame, a self adhesive tape is available.

-

Oven gasket stove gasket grilling closure textile gasket high temperature gasket

It is a highly resilent textile gasket designed for high temperature applications. The outer surface is composed of multiple intertwined fiber glass yarns that form a rounded tube. To improve the resiliency of the gasket, a special supporting tube made of stainless steel wire is inserted inside one of the inner cores, another inner core is a braided cord which also offers a strong support to the gasket. This allows a superior life cycle while keeping constant spring effects.

-

GLASFLEX braided sleeve anti high temperature excellent insulation sleeving flexible and expandable sleeve

GLASFLEX UT is a braided sleeve using continuous fiberglass filaments that is able to withstand high temperature in continuous up to 550 ℃. It has excellent insulation capabilities and represents an economic solution to protect pipes, hoses and cables from molten splashes.

-

High temperature resistant rope gasket Fiberglass knitted soft cord Fiberglass knitted rope seal

Our soft knitted rope produced with texturized E-grade fiberglass yarns. The filamentshave thin diameters of 9µm and undergo to a pressurized air jet to generate higher volumebetween the single filaments. Additionally, to increase the temperature resistance, the knittedrope is coated with a special coating formulation that protects the single filaments against longtime exposure to high temperature sources. -

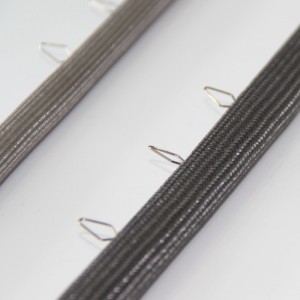

Thermo gasket oven door replacement clip gasket glass seal with hook fiberglass seal

Thermo gasket is a highly resilient textile gasket designed for high tempereture applications. The outer surface is composed of multitwined fiber glass yearn that found a rounded tube.To improve the resiliency of the gasket a special supporting tube made of stainless steel wire is inserted inside the tube. Stainless steel clips are used to fix the gasket to the applications firmly.

-

Thermtex braided tape for oven self adhesive heat resistant strip high temperature seal

In the stove industry, Thermetex® offers multiple reliable solutions which are able to withstand high operating temperatures. Raw materials used are commonly based on fiberglass filaments, treated with custom designed processes and specifically developed coating materials. The advantage of doing so, it is to achieve higher working temperatures. Additionally, where easy installation is required, pressure activated adhesive backing have been applied to the gasket to facilitate and accelerate the mounting process. During assembly of parts, like glass panels to the stove door, fixing first the gasket to one assembly element can be very helpful for a prompt mounting operation.

-

Glassflex with High Modulus Characteristic and High Temperature Resistance

Glass fibers are man made filaments originated from components found in nature. The major element contained in fiberglass yarns is the Silicon Dioxiode (SiO2), which confers the high modulus characteristic and high temperature resistance. Indeed, fiberglass are not only having high strength compared to other polymers but also an outstanding thermal insulator material. It can withstand continuous temperature exposure more than 300℃. If it undergoes to post-process treatments, the temperature resistance can be further increased up to 600 ℃.

-

Thermtex Suit Well to Most Equipment Glass seal for high temperature applications

Thermtex® include a wide range of gaskets produced in a variety of forms and styles that suit well to most equipment. From high temperature industrial furnaces, to small wood stoves; from large bakery ovens to home pyrolytic cooking ovens. All items have been classified in base of their temperature resistance grade, the geometrical form and area of application.